This part of Minnesota is a mixed Laurentian forest on the edge of what was once The Big Woods, detailed eloquently in Laura Ingalls Wilder's book of the same name. The Big Woods covered a huge area of the United States; mostly a mix of Elm, Oak and Sugar Maple that thinned out as it reached the open prairie grasslands of the Midwest.

|

| A backyard evaporator |

The cycle of cold nights and warm days in this part of the country begins to bring the trees alive. It will be weeks before bud break but the sap is now running full tilt. Maple sugaring, once common practice in the northern U.S., has given way to the use of table sugar purchased at the local mega grocer and consumed by the pound. But it does still exist both in small scale commercial operations and backyard 'sugar shacks' in this area.

|

| Collecting sap |

When I went looking for local syrup in my neighborhood, blue bags hanging from trees scattered through the woods told me I had found what I was looking for. I stopped my car to chat with a group of friends boiling down sap in the yard of their friend, a disabled Vietnam Vet. They tap 130 or more maple trees each year and create a product he can sell from his home. Their handmade evaporator was a simple wood firebox with a shallow evaporating pan attached to the top. Stainless steel sheets laid across the top created condensation and allowed the excess water to drip away.

|

| 30 gallons of sap will make less than a gallon of Syrup |

|

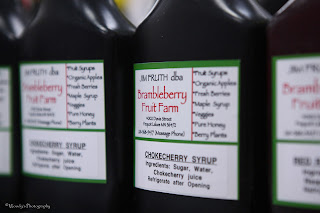

| Brambleberry Farm makes Fruit Syrups & Pure Maple Syrup |

Another nearby producer, Jim Fruth from Brambleberry Farm in Pequot Lakes, has been sugaring since the early 1970's. He creates an amazing array of products from his small acreage of over a dozen different fruits and berries. Sumac Syrup, Blueberry Hot Pepper Sauce, Raspberry Jalapeno Jam and Chokecherry Syrup are common products at his local farmer's market stall.

|

| Jim Fruth at his evaporator |

Jim taps 250-300 maple trees in an average year and spends weeks at his evaporator creating syrup to sell throughout the season. He is innovative about the process, adding a 'bubbler' to his evaporator to speed the evaporation process and filtering his sap a total of 5 times before bottling. This is clearly not a hobby for Jim but it clearly is a labor of love. He allows me to taste the raw sap and I am shocked that it has almost no flavor. It is only the beautiful slightly caramelly aroma from the evaporator a few yards away tells of what will come.

|

| You will find lots of unusual and flavorful goodies at Brambleberry Farm |

As I drive the few miles back home, I wonder how we have become so separated from the food we eat. Why is the making of this ancient American sugar a complete mystery to me? When did high fructose corn syrup, mixed with chemical colorants and 'maple flavoring' that actually contains no maple at all, replace this amazing and delicate delight of spring? Comparing the two on the grocery store shelf seems silly; as if comparing a steak to a head of lettuce. How have we come to believe that a completely artificial chemical concoction is maple syrup? Hmm.

|

| Spiles are used to tap maple trees |

|

| Sap collection buckets |

|

| Tube style taps |

Making real maple syrup involves hiking through the woods in March and April, drilling trees, tapping in the spiles and hanging your containers. Once or twice daily, you empty each container (often a gallon or more), carry it back to your evaporator, filter the lot and begin boiling down the sap. A single gallon of maple syrup is produced from about 40 gallons of sap.

|

| Tubes are linked & empty into a pail |

No wonder corporations would rather feed us a mixture of ingredients that smell 'mapley'. This is real work with highly varied results from year to year. If the weather is just right, you get a great deal of sap. If springtime nights are too warm or the weather changes too quickly, you may get little return for your trouble.

|

| Red paint makes it easier to identify trees quickly when tapping |

|

| Future Maple Trees |

When Severt Aarhus emigrated from Norway in 1894 at the age if 19, he came to this area to farm a 160 acre homestead near South Long Lake, a few miles south of Brainerd, Minnesota. He farmed the fields and managed his mixed woods of birch, oak and sugar maple until his death in 1972. I like to think he would be proud to know, 39 years after his death, that his great-great grandchildren are sugaring in the same beautiful woods, gathering sap in much the same manner as he did over his lifetime on the farm.

|

| The new 'sugar shack' at Severt's Woods |

The only difference is the soon-to-be commercially licensed sugaring operation on the property. Kent Montgomery, Severt's great grandson, recently built a commercial building and evaporator and hopes to be distributing his product in local stores next spring.

|

| Commercial Evaporator at Severt's Woods |

Like many others in the area, Kent and his wife Paula are able to sell their product from their home or at farmers markets and festivals, but not commercially without the steps he is now taking. Once the current process is complete, they will be able to sell their product to local groceries and co-ops. The down side? He has had to work with no less than 6 regulatory agencies in the state and county in order to take his product to a larger audience.

I, personally, find it confusing that the syrup is considered perfectly safe to sell to people from a roadside stand, even if it is boiled over a campfire in your backyard, but to sell it inside the local co-op, one needs to invest tens of thousands of dollars. Kent is not building a factory. He is tapping fewer trees than many of the backyard producers I met. He is boiling sap and sealing it in sterile bottles as he has done safely for years. Yet the government regulates him as a food processing plant on the same scale as General Mills.

|

| Collecting one drop at a time |

Don't get me wrong, food safety is a serious thing, but it is not the little guys who are making people sick. Jenny-O is one of dozens of mass producers currently in the news, once again issuing recalls on their own factory produced products. Factory-farmed eggs, mass produced peanut butter and ground beef have all been recent culprits of food borne illness on a national level.

|

| Sap buckets |

Is it possible for us to get to a point where we have reasonable legislation for artisan producers that does not put the kind of financial pressure on small producers as the label “organic” has done? How can we allow start up companies of artisan products to thrive if they cannot afford to test the market on a small scale and grow? Or to decide to work happily on a small local scale forever?

|

| Severt's Woods Pure Maple Syrup |

I walked into my local grocery store yesterday and stood in the syrup aisle. There were three shelves filled with dozens of brands of 'artificial maple flavored' corn syrup and one brand of pure maple syrup. It was made in New York state. How far have we come from young Severt's woods? A very long way.

Maple & Banana Walnut Pancakes

These rich, filling pancakes are easy to make and chock full of bananas. Perfect for brunch after a hike in the woods.

2 cups Organic Unbleached Flour

½ cup Brown Sugar, firmly packed

½ tsp Baking Soda

1 tsp aluminum free Baking Powder

1/8 tsp Kosher Salt

3 medium Bananas

½ cup Pure Maple Syrup

1/2 tsp each Cinnamon & freshly grated Nutmeg

2 Eggs, slightly beaten

2 cups Buttermilk

¼ cup (½ stick) Butter, melted

½ cup lightly toasted Walnuts, chopped

In a large bowl combine the flour and the brown sugar. Whisk in the baking soda, baking powder and salt. Set aside.

Mash the bananas together with the maple syrup and spices in a medium bowl. Add the eggs and buttermilk and mix thoroughly.

Mash the bananas together with the maple syrup and spices in a medium bowl. Add the eggs and buttermilk and mix thoroughly. Add the buttermilk mixture to the dry ingredients all at once and stir just to combine. Mixture will have some lumps. Stir in the melted butter and the walnuts.

Preheat a flat griddle over medium heat. Grease the griddle lightly with butter. Pour the batter, 1/3 cup at a time onto the greased griddle. Bake for 1 ½ – 2 minutes per side.

Cakes may be held in a 200 degree oven on a warm plate until all are baked and ready to serve.

Serve the banana pancakes with butter and lots of local Pure Maple Syrup. Serves 6.

Recipe Notes:

- If the batter is too thick, add milk, 1 Tbsp at a time.

- Producers who are not commercially licensed may not advertise their products under current law. Look for locally produced 'PURE MAPLE SYRUP' at your farmers market, watch for roadside signs or ask around.

- Vote with your dollars. Pure Maple Syrup is not cheap because it is not cheap to produce. Ask your grocer to bring in Pure Maple Syrup made by small commercial producers in your area.

- Introduce your friends and family to local, Pure Maple Syrup. You will be amazed at the number of people who have never experienced the real thing.

- Add Pure Maple Syrup to sweet potatoes, butternut squash, carrots, and other veggies for variety from boil 'em & butter 'em boredom. You can add spices like Cinnamon, Cardamom, Nutmeg, etc. too, for a whole new taste treat.

- Maple is a great flavor in baking also. Try it in oatmeal cookies and quick breads.When substituting Maple Syrup for Granulated Sugar in baking: Instead of 1 cup of granulated sugar in recipes, use ¾ -1 cup of maple syrup, to taste. In baking, reduce the liquid by 2-4 tablespoons per 1 cup maple syrup used, add 1/4 tsp baking soda and reduce the oven temperature by 25 degrees. Your finished product will carry some of the flavor of the maple syrup. (try this in oatmeal cookies!)

No comments:

Post a Comment